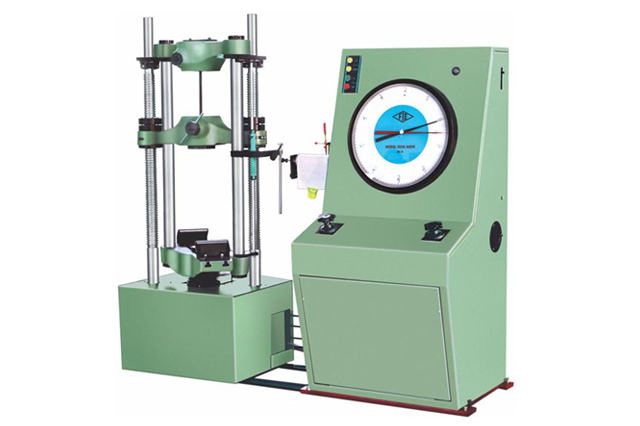

Universal Testing Machine

Applications

UNIVERSAL TESTING MACHINE are closely controlled for sensitivity, accuracy and calibration during every stage of manufacture .Every Machine is then calibrated over each of its measuring ranges. Universal Testing Machine have a wide range of applications. A number of materials, metals in different form and shapes can be tested for variety of tests like Tension, Compression, Bend, Shear etc.

Features

Others Optional Accessories

Mechanical Extensometer, Load-Stabilizer, Attachments for Brinell test, Tensile test for shouldered & threaded, Single & Double shear test, Bolts-Nuts & Washer test, Rope test, Flat Belt test, Bend test, 180° Bend test, Pull-Out test, etc. are available.

Operation

For Operation of UNIVERSAL TESTING MACHINE is by hydraulic transmission of load from the test specimen to a separately housed load indicator. The system is ideal since it replaces Transmission of load .Tension test is conducted by gripping the test specimen in the upper and middle cross head. Compression, Bending, Shear tests are conducted between the middle and lower cross head by using appropriate fixtures. The rapid adjustment of middle cross head facilities easy fixing of tensile I Compression specimens of different lengths. Hydraulic controls are through hand operated valves, ergonomically placed for ease of control. Optionally valves can be controlled from electronic control system. Adequate safeties for over load and over travel are incorporated and emergency switch is provided.

Load Measurement System

In the UNIVERSAL TESTING MACHINE oil pressure in the main cylinder is also transferred to an electronic pressure transducer which goes proportionate signal to computer electronic unit. Both the motors for hydraulic operation and cross head motion are controlled by buttons on electronic control system and they have interlocks to prevent simultaneous working of motors. The electrical panel is housed in control panel. Displacement measurement is carried out by means of a rack and pinion on rotary encoder. Encoder signal is fed to electronic control system to get displacement.

Balitikuri, Dasnagar,

howrah-711113

Newsletter

finetechnoengineering 2024 All right reserved | Developed By Digital Zoneway